PART OF CATALOG

KPS-Prazisionsspannzange KPS 16 | < 5µm | O 8,0-7,5

Plug gauge | 17mm | H7 accuracy DIN 7162|7164 | size DIN 2245

HSSE twist drill 135° 9,0 mm DIN 338 | TIN coating

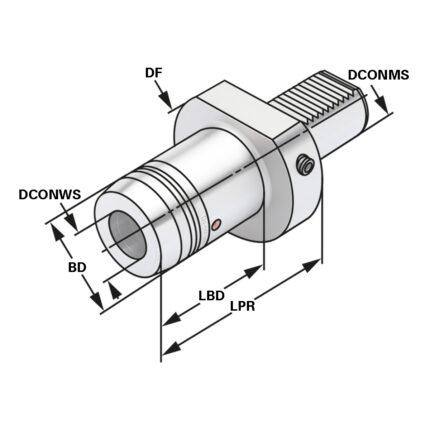

Hydraulic expansion chuck 40 – 12 – 60

Machine vices ATI-175 mechanical

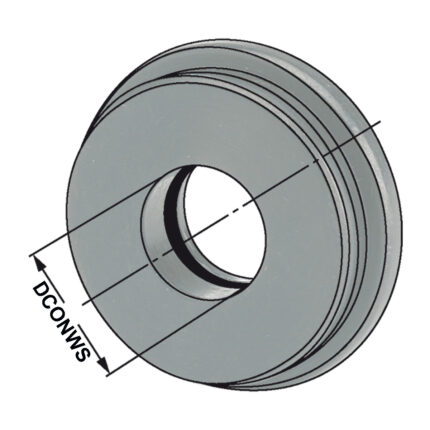

Sealing disc | ER 16 DCONWS = 5,0

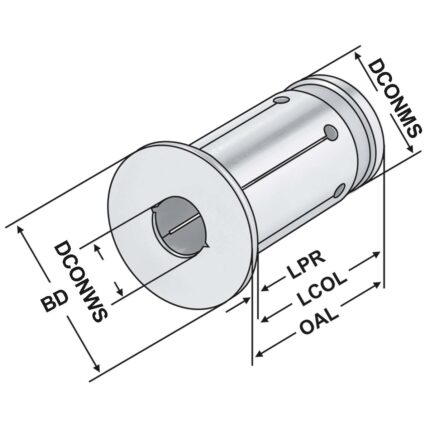

Reduction sleeves for Milling Chuck DCONMS=20 | DCONWS=4

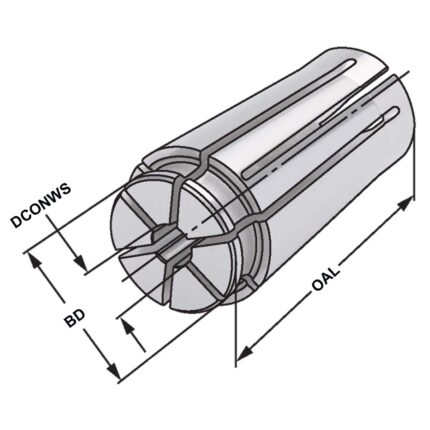

ER-Collet with cooling channel holes ER20 | 428EC | < 15µm | O 7

FREE CONSULTATION