PART OF CATALOG

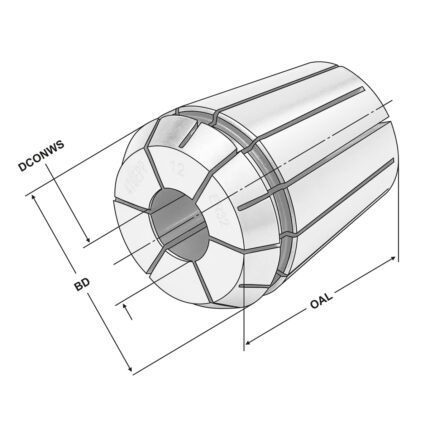

ER-Collet with cooling channel holes ER40 | 472EC | < 15µm | O 9

ER-Precision collet ER40 | 472EP | < 5µm | O 23 - 22

ER-Precision collet ER32 | 470EPP | < 3 µm | O 9,0

Collets - Precision - 3 µm, 470 E (ER 32) - Precision - 3 µm, Collets system ER - Precision - 3 µm, Collets

Application:

For mounting straight-shank tools in collet chucks ISO 15488 (ex. DIN 6499).

Version:

System concentricity and repetition accuracy 3 µm (3?D, maximum = 50 mm), in conjunction with KEMMLER Precision collet chuck ER".

Suitable for:

KEMMLER Precision collet chuck ER or standard collet chuck Spannfutter ISO 15488 (ex. DIN 6499).

Note:

The collet clamping O range is always up to 0.5 mm less than nominal.

ER-Collet with cooling channel holes ER40 | 472EC | < 15µm | O 25

Precision vice AVQ-160G/HV mechanical with mechanical booster

Construction:

- With mechanical booster - Clamping force preadjustable by graduation lines

- Clamping positions: horizontal, vertical and lateral

- The steel body is hardened and grinded all-round

- Integrated pull-down mechanism

- Bed height H: 0,01 mm

Delivery:

- Instructions for use

- Wrench

- 4 pcs. vice clamps

- 4 pcs. T-nuts 18 mm

- Test certificate

Quick change tapping chuck 30 – M3-M14 – Gr.1

Milling arbors for screw-in cutters BT 50 – M10 – 138 – LB100

Application:

For mounting screw-in cutters with thread.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Morse taper adaptor BT 40 – 1 – 50

FREE CONSULTATION