PART OF CATALOG

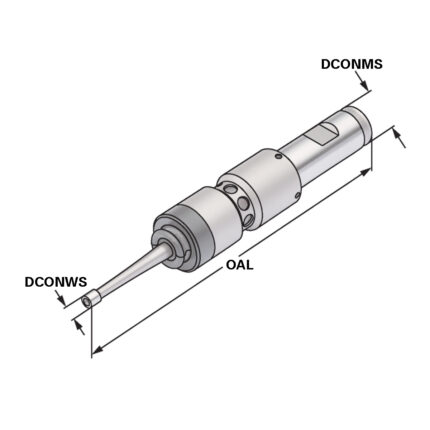

Reduction sleeves for hydraulic expansion chucks DCONMS=20 | DCONWS=12

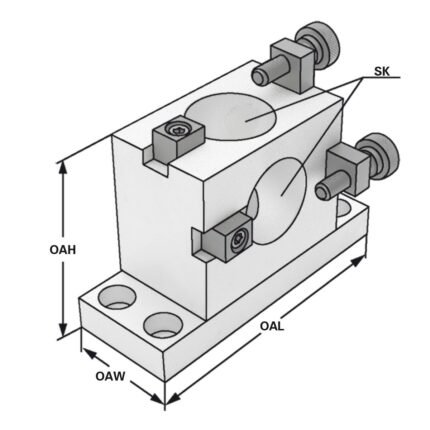

CNC-Drill chuck SK 40 – 0,5/8 – 63

Application:

For mounting tools with straight shanks.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Solid carbide ball nose end mill 2 flutes short 2m R1,0 – 6 AlTiCrN coating

Milling arbors for screw-in cutters HSK 63 – M10 – 76 – LB50

Application:

For mounting screw-in cutters with thread.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Kantentaster elektronisch 3D 20 – 173 – 6

Application:

Alignment of component reference surfaces or edges. Determination of bore centres to the machine spindle.

Note:

Function: When contact with the metal component occurs, the control lamp lights up = identification of the reference point.

Version: The contact point has a flexible connection to the body via a spring, with an alignment accuracy of 0.01 mm. All parts fully hardened and ground.

Delivery:

LR1N Batterie 1,5V

FREE CONSULTATION