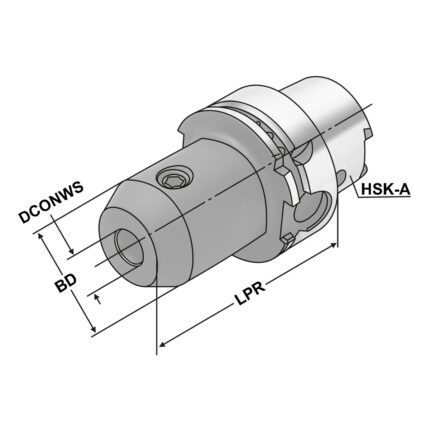

End mill holder Weldon HSK 63 – 25 – 110

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Hohen-Einstellgerat elektronisch (mit Magnet)

Application:

To determine position of workpiece surfaces or workpiece lengths in Z-direction on lathes or milling machines.

Note:

The apparatus is placed on the workpiece. With the spindle, now move carefully to the device. As soon as the LED lights up, you have achieved the reference value 50 mm. A safety spring way of approx. 3 mm to cross 50 mm is integrated.

Delivery:

2x SR44W batteries

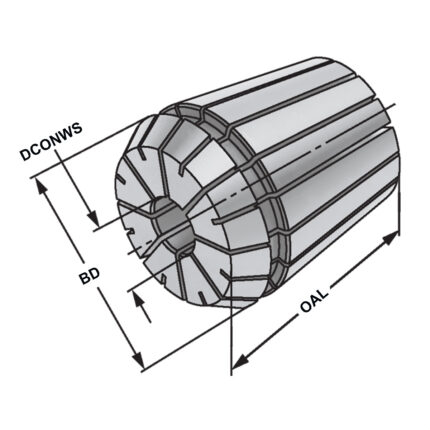

ER-Collet ER25 | 430E | < 15µm | O 11 - 10

Quick change tapping chuck SK 40 – M3-M14 – Gr.1

Application:

For the chucking of quick change adaptors for taps.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Hydraulic expansion chuck BT 40 – 20 – 150

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Without wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Milling arbors for screw-in cutters SK 50 – M12 – 169 – LB150

Application:

For mounting screw-in cutters with thread.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

OZ-Collet OZ32 | 467E | < 15µm | O 11 - 10,5

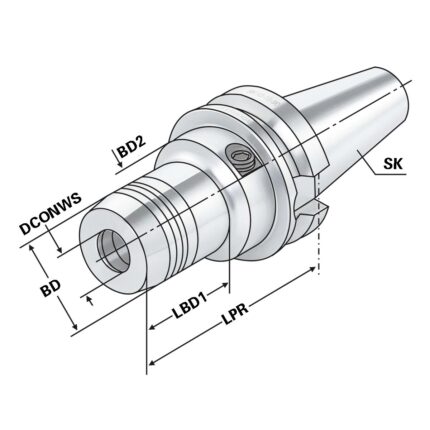

End mill holder Weldon SK 50 – 08 – 160

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined