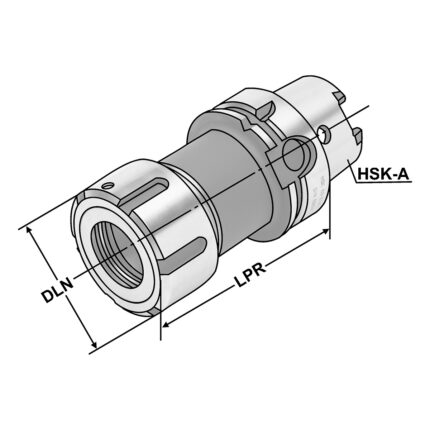

OZ-Collet chuck HSK 63 – 2/25 – 100 | OZ 25

Application:

For mounting straight-shank tools in collets.

Delivery:

With ball bearing clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

OZ-Precision collet OZ32 | 467EP | < 5µm | O 23 - 22,5

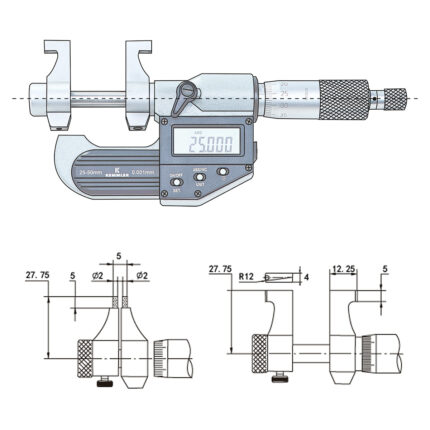

Inside micrometer | digital | 50-75mm with data output | IP 65

Construction:

- Resolution: .00005" / 0.001mm

- Designed for the measurement of intricate internal characteristics

- cartide tipped measuring sufaces

- Satin chrome finished

- 5-30mm and 25-50mm range are supplied with setting rings

- Ratchet stop

Delivery:

- S-wrench

- Warranty card

- Instruction manual

- Calibration certificate

- LR44 1,5V Battery

Hydraulic expansion chuck BT 40 – 32 – 150

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Without wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Quick change tapping chuck BT 40 – M5-M22 – Gr.2

Application:

For the chucking of quick change adaptors for taps.

Note:

For machining centres with synchronous spindle.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Morse taper adaptor SK 50 – 5 – 120

Application:

For clamping tools with Morse taper shank and thread according to DIN 228-1 form A.

Delivery:

With built-in tightening bolt

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Combi shell mill holder BT 40 – 27 – 160

Application:

For mounting milling cutters with transverse or longitudinal groove.

Delivery:

With retaining screw, driving ring and feather key

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined