End mill holder Weldon with cooling channels HSK 63 – 06 – 130

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw and O-ring

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Shell mill holder BT 40 – 40 – 50

Application:

For mounting milling cutters with transversal groove.

Note:

d = 40/d = 60: For large diameter face mill cutters with four additional threaded holes according to DIN 2079.

SK 30 without coolant exit bores on the end face

Delivery:

With drivers, cross head retaining screw and cylinder head retaining screw for cutters with central coolant. For d = 60 only with four fi xation screws according to DIN 912.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

ER-Collet chuck HSK 32 – 1/10 – 50 | ER 16 | Mini

Application:

For mounting straight-shank tools in collets.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

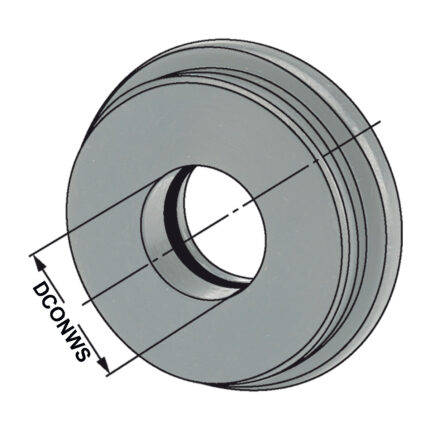

Sealing disc | OZ 16 DCONWS = 9,5

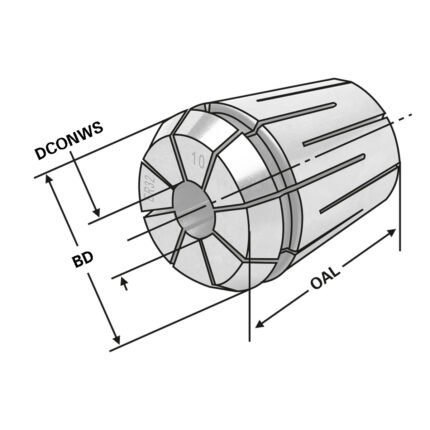

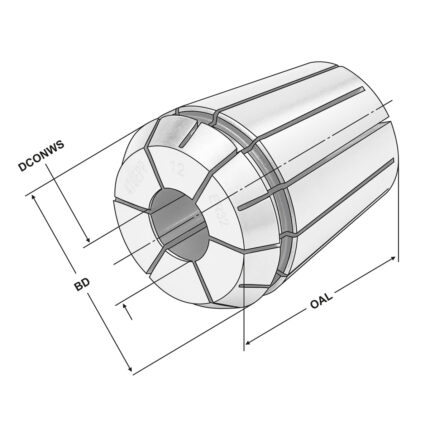

ER-Precision collet ER32 | 470EPP | < 3 µm | O 4,5

Application:

For mounting straight-shank tools in collet chucks ISO 15488 (ex. DIN 6499).

Version:

System concentricity and repetition accuracy 3 µm (3?D, maximum = 50 mm), in conjunction with KEMMLER Precision collet chuck ER".

Suitable for:

KEMMLER Precision collet chuck ER or standard collet chuck Spannfutter ISO 15488 (ex. DIN 6499).

Note:

The collet clamping O range is always up to 0.5 mm less than nominal.

CNC-Drill chuck HSK 40 – 2,5/16 – 126

Application:

For mounting tools with straight shanks.

Delivery:

With wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined