20

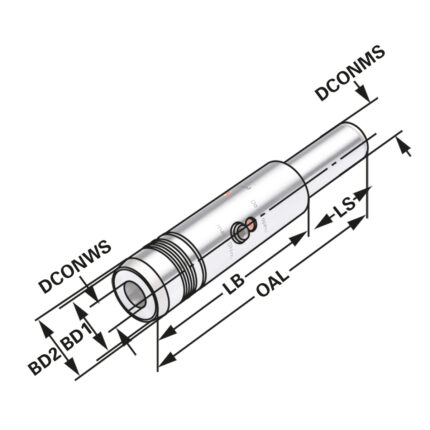

Edge finder mechanical 3D 20 – 4 – 162,50

Application:

Search for the neutral point and raise in 3-axis, x, y and z.

Version: Raise the tool edge assigned as neutral point in x- or y-way with the edge sensor until both pointers of the dial gage are at zero. At that moment the key-edge is equal to the spindle-axis. In z-way direct way-measurement.

IP 67 waterproof

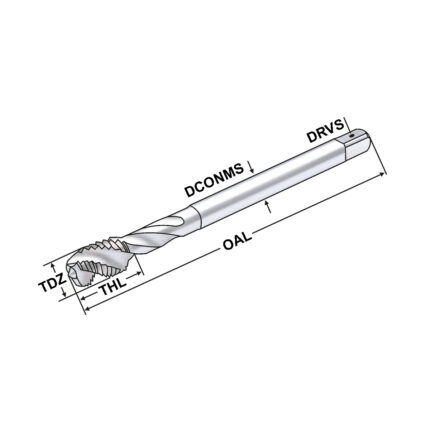

HSS-E spiral flute taps M27 20×16 P=3,0

Application:

- Thread confi guration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

HSS-E spiral flute taps M27 20×16 P=3,0

Application:

- Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

HSS-E spiral flute taps M27 20×16 P=3,0

Application:

1. Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

2. Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

3. Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

HSS-E spiral flute taps M27 20×16 P=3,0

Application:

- Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel