25

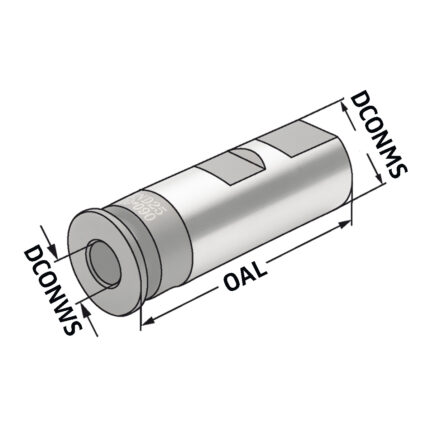

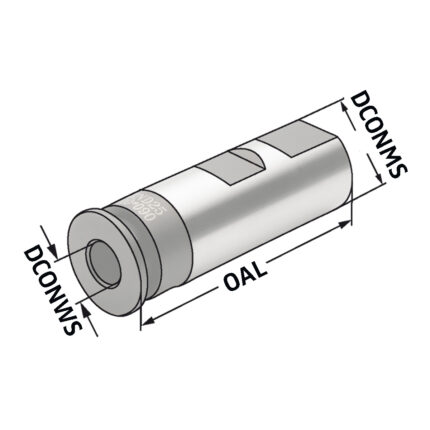

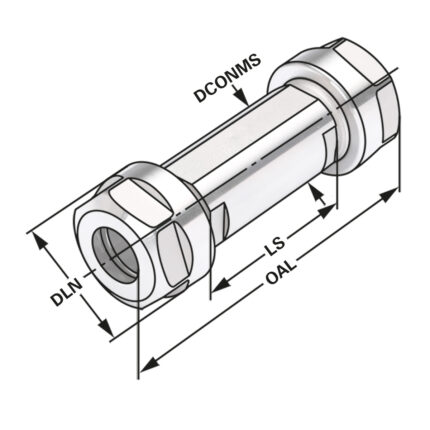

Clamping sleeves for taps with quick change DCONMS=25 | 12 x 9

Clamping sleeves for taps with quick change DCONMS=25 | 4,5 x 3,4

Clamping sleeves for taps with quick change DCONMS=25 | 6 x 4,9

Clamping sleeves for taps with quick change DCONMS=25 | 7 x 5,5

Clamping sleeves for taps with quick change DCONMS=25 | 8 x 6,2

Clamping sleeves for taps with quick change DCONMS=25 | 9 x 7

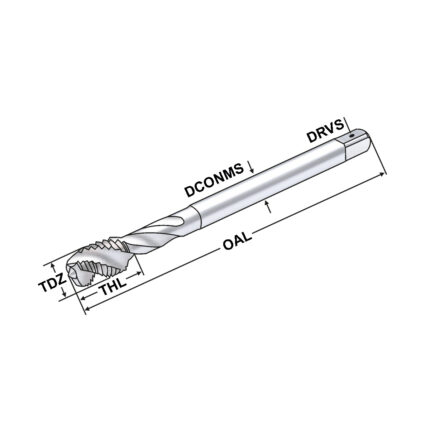

HSS-E spiral flute taps M33 25×20 P=3,5

Application:

- Thread confi guration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel