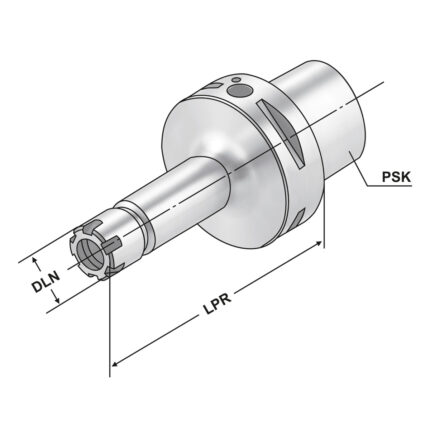

Product information “End mill holder Weldon with cooling channels PSK 63 – 10 – 100”

End mill holder Weldon with cooling channels PSK 63 – 10 – 100

€289.00

| ADINTMS |

CCS – Polygonschaftkegel |

|---|---|

| ADINTWS |

DIN 6359 (Weldon) |

| Auswuchtgüte |

25.000 1/min, G2,5 |

| BD | |

| CXSC | |

| DCONWS |

10 |

| LPR |

100 |

| PSK | |

| Rundlauf |

< 3µm |

| TDCON |

Order Number:

C6.04.10.1.K

Categories: End mill holders with coolant c., ISO 26623 (PSK)

Related products

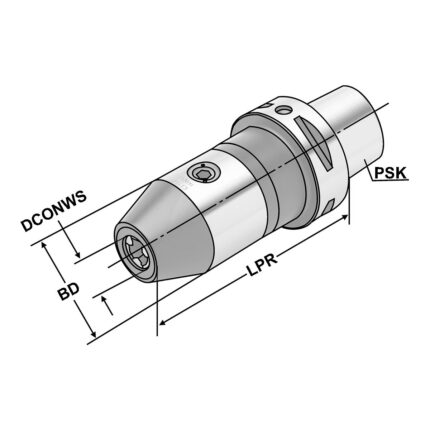

CNC-Drill chuck PSK 63 – 2,5/16 – 117

€520.00

Application:

For mounting tools with straight shanks.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Test arbor PSK 63 – 40 – 182

€795.00

Application:

For the inspection of machine tools according to ISO recommendation R230 or for testing the tool spindle.

Delivery with test certificate

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined