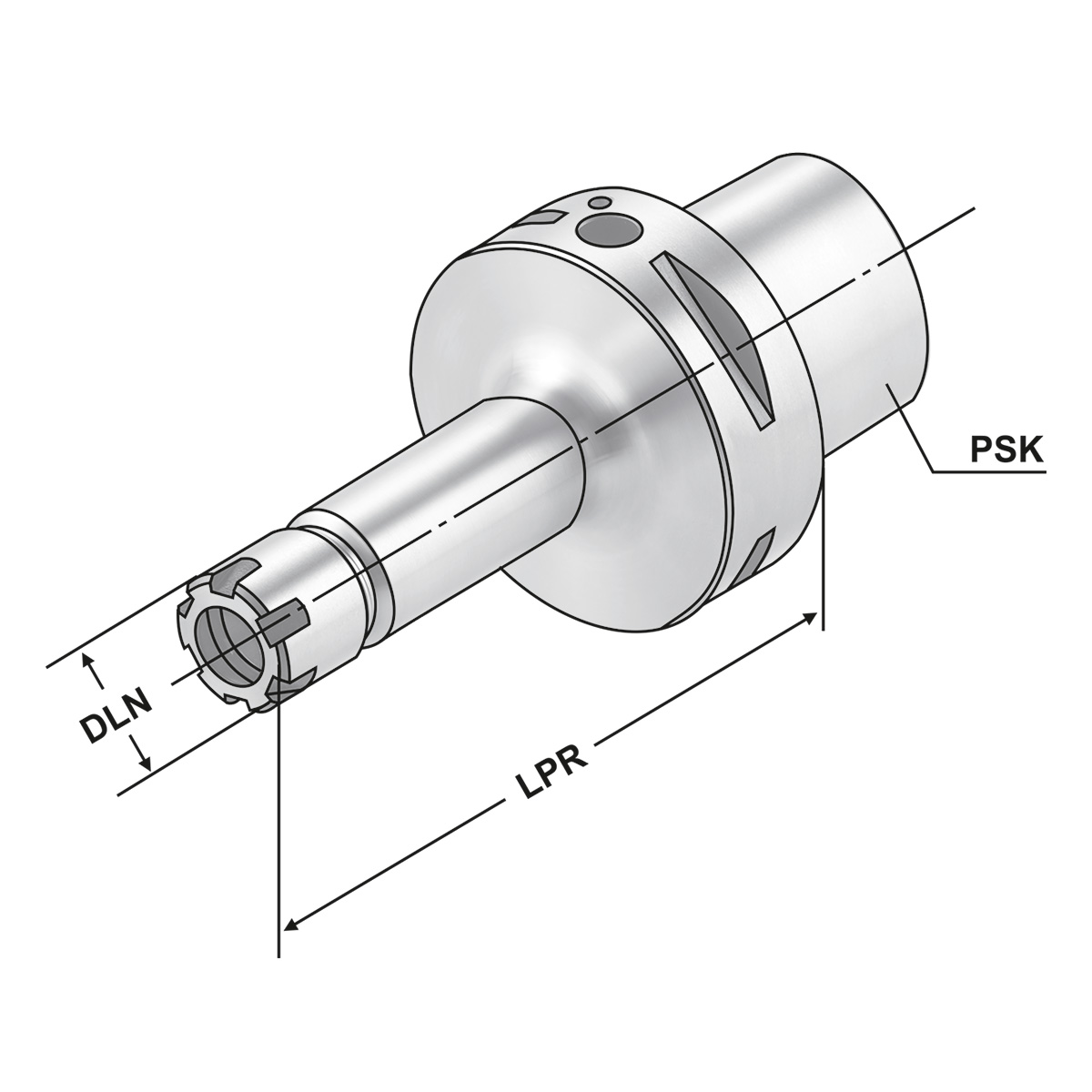

Product information “ER-Collet chuck PSK 63 – 1/10 – 100 | ER 16 | Mini”

ER-Collet chuck PSK 63 – 1/10 – 100 | ER 16 | Mini

€286.00

| Typ |

426E, ER 16 |

|---|---|

| ADINTMS |

CCS – Polygonschaftkegel |

| ADINTWS |

ISO 15488 (DIN 6499) ER |

| Auswuchtgüte |

25.000 1/min, G2,5 |

| DCONWS |

1 – 10 |

| DLN |

22 |

| LPR |

100 |

| PSK | |

| Rundlauf |

< 3µm |

| THID |

M10x1 |

Related products

CNC-Drill chuck PSK 63 – 1/13 – 112

Application:

For mounting tools with straight shanks.

Delivery:

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Test arbor PSK 40 – 32 – 180

Application:

For the inspection of machine tools according to ISO recommendation R230 or for testing the tool spindle.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Zwischenhulse fur ISO 26623 (PSK) HSK 63 – PSK 50 – 90

Application:

For adaption from HSK-A to PSC (ISO 7388-1 to ISO 26623-1)

Delivery:

Clamping screw

Version:

Adapters HSK / PSK with axial clamping. Ground internally and externally. The internal thread provided for the coolant tube in the PSC toolholder is plugged with the socket-head screw incorporated in the adapter. The clamping screw incorporates a through hole, so the system is suitable for through-coolant feed. Suitable for tool arbor with polygonal shank (PSC) - ISO 26623-1.