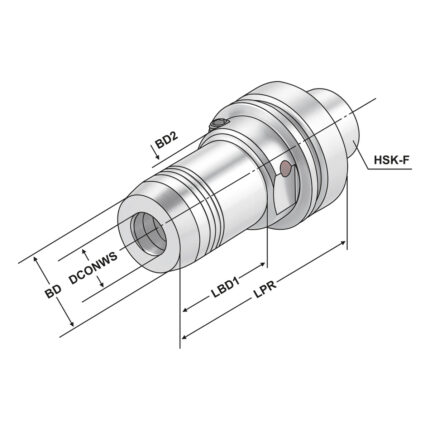

Product information “Hydraulic expansion chuck PSK 40 – 12 – 70”

Hydraulic expansion chuck PSK 40 – 12 – 70

€399.00

| ADINTMS |

CCS – Polygonschaftkegel |

|---|---|

| ADINTWS |

Hydro-Dehnspannfutter |

| ADJRGA | |

| Auswuchtgüte |

25.000 1/min, G2,5 |

| BD | |

| BD2 | |

| DCONWS |

12 |

| DRVS |

5 |

| LBD1 | |

| LPR |

70 |

| LSCX | |

| PSK | |

| Rundlauf |

< 3µm |

| THID |

M8x1 |

Order Number:

C4.H12

Categories: Hydraulic chucks special offer 2023, ISO 26623 (PSK), New items

Related products

Hydraulic expansion chuck HSK 63 – 6 – 100

€319.00

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Delivery:

Without wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

ER-Precision collet chuck HSK 63 – 2/20 – 100 | ER 32

€129.00

Application:

For mounting straight-shank tools in 2 µm-collets.

Advantage:

- Excellent concentricity in the system (chuck + collet + clamping nut)

- 3 µm radial run-out with a 2 µm clamping nut, 6 µm radial run-out with a 5 µm clamping nut

- Extremely strong holding force (increases the holding power by at least 60% compared to standard ER chuck)

- Plain clamping nut without grooves for high speed machining

ER-Precision collet chuck PSK 40 – 2/20 – 70 | ER 32

€370.00

Application:

For mounting straight-shank tools in 2 µm-collets.

Advantage:

- Excellent concentricity in the system (chuck + collet + clamping nut)

- 3 µm radial run-out with a 2 µm clamping nut, 6 µm radial run-out with a 5 µm clamping nut

- Extremely strong holding force (increases the holding power by at least 60% compared to standard ER chuck)

- Plain clamping nut without grooves for high speed machining

Hydraulic expansion chuck SK 40 – 18 – 80

€372.00

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Without wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined