h4

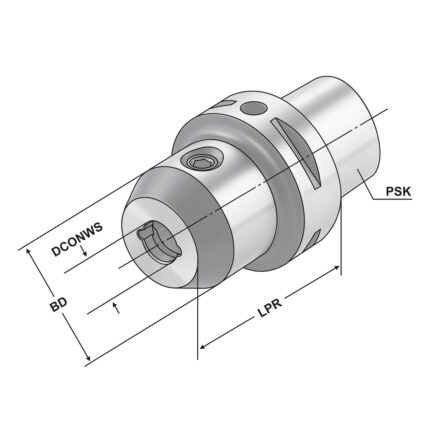

End mill holder Weldon PSK 63 – 32 – 90

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

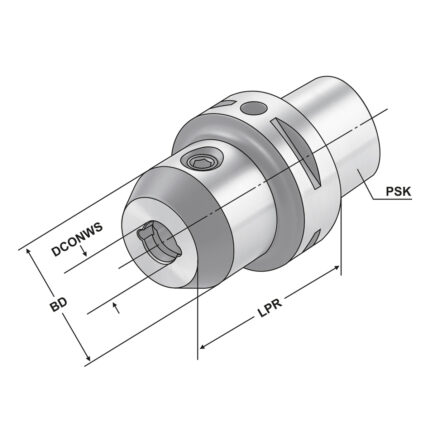

End mill holder Weldon PSK 63 – 40 – 100

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

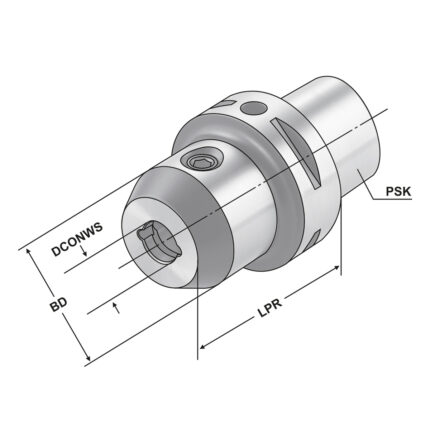

End mill holder Weldon with cooling channels PSK 63 – 06 – 100

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

With coolant channels for optimal coolant at the cutting edge.

Delivery:

With clamping screw

Note:

From DCONWS = 25 on two clamping screws

DCONWS = 6 to 18 with two coolant channels

DCONWS = 20 to 40 with four coolant channels

For tools with through coolant an O-ring must be used.