PART OF CATALOG

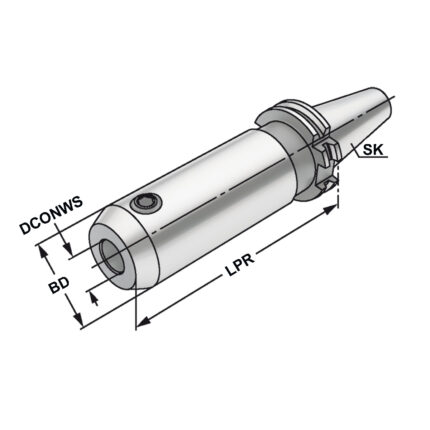

ER-Precision collet chuck HSK 40 – 2/20 – 70 | ER 32

Application:

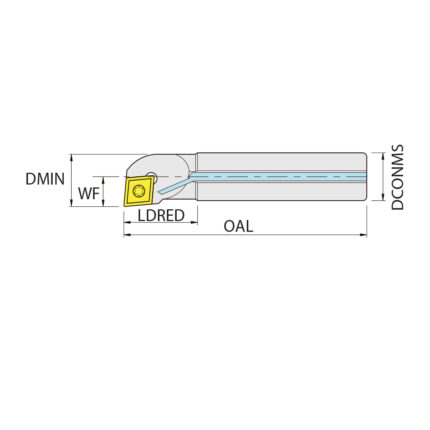

For mounting straight-shank tools in 2 µm-collets.

Advantage:

- Excellent concentricity in the system (chuck + collet + clamping nut)

- 3 µm radial run-out with a 2 µm clamping nut, 6 µm radial run-out with a 5 µm clamping nut

- Extremely strong holding force (increases the holding power by at least 60% compared to standard ER chuck)

- Plain clamping nut without grooves for high speed machining

Morse taper adaptor – form F1 F1 – 20 – MK2

Swivel base for machine vice HP-40

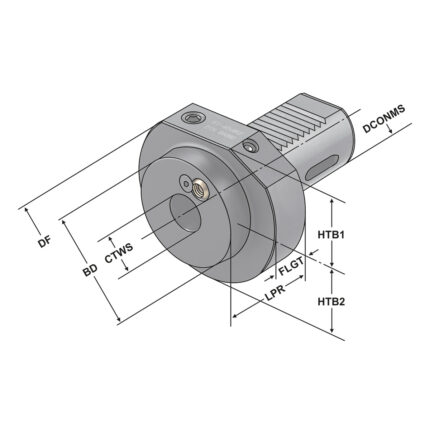

Hydraulic expansion chuck BT 50-25-110 JIS B 6339 (MAS-BT) AD/B in wooden box

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Delivery:

With wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

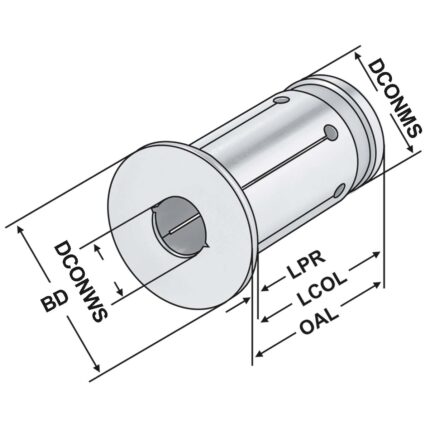

Reduction sleeves for hydraulic expansion chucks DCONMS=20 | DCONWS=3

FREE CONSULTATION