PART OF CATALOG

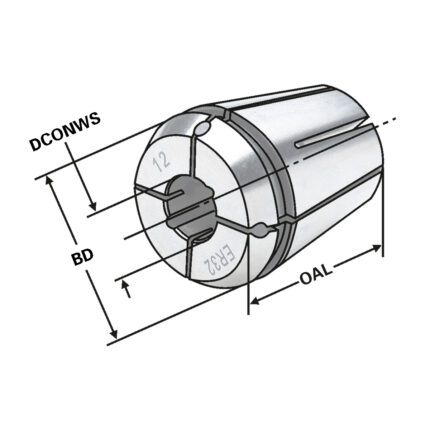

OZ-Collet OZ32 | 467E | < 15µm | O 30 - 29,5

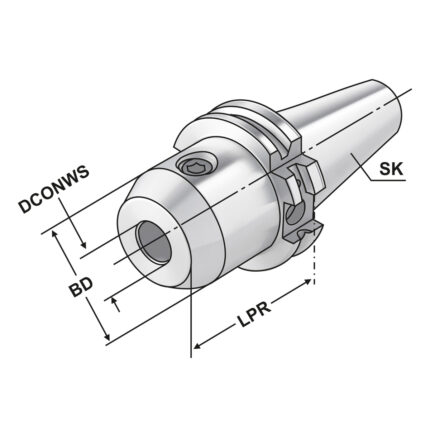

End mill holder Weldon SK 40 – 25 – 100

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

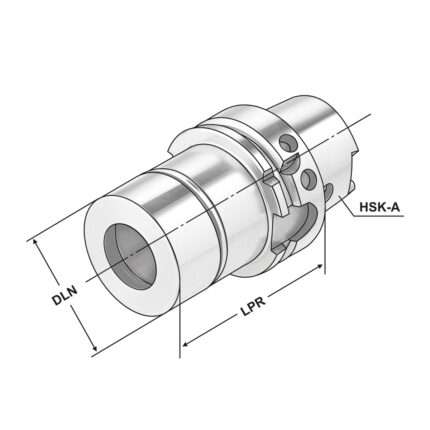

ER-Precision collet chuck HSK 100 – 2/20 – 100 | ER 32

Application:

For mounting straight-shank tools in 2 µm-collets.

Advantage:

- Excellent concentricity in the system (chuck + collet + clamping nut)

- 3 µm radial run-out with a 2 µm clamping nut, 6 µm radial run-out with a 5 µm clamping nut

- Extremely strong holding force (increases the holding power by at least 60% compared to standard ER chuck)

- Plain clamping nut without grooves for high speed machining

End mill holder Weldon with cooling channels SK 50 – 25 – 130

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw and O-ring

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

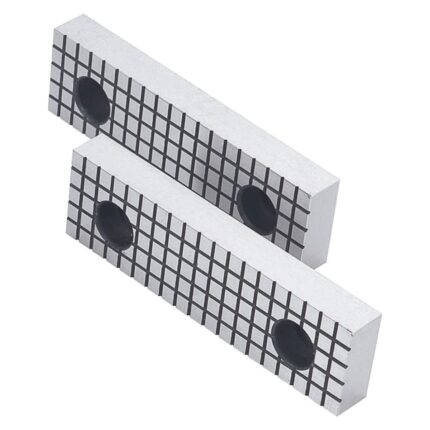

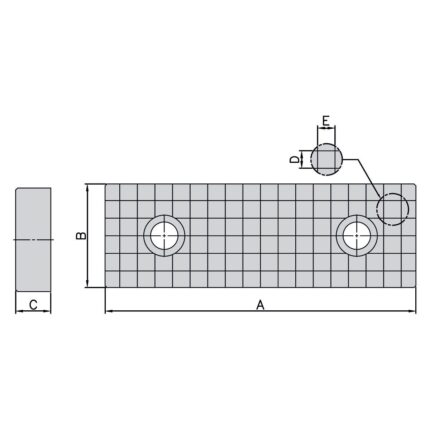

Shell mill holder HSK 40 – 16 – 50

Application:

For mounting milling cutters with transversal groove.

Note:

d = 40/d = 60: For large diameter face mill cutters with four additional threaded holes according to DIN 2079.

Delivery:

With drivers, cross head retaining screw and cylinder head retaining screw for cutters with central coolant. For d = 60 only with four fi xation screws according to DIN 912.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

ER-Spannzange mit Kuhlkanalen ER20 | 428ECC | < 15µm | O 6

FREE CONSULTATION