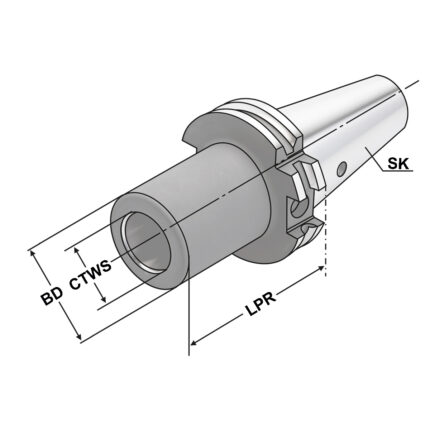

Hydraulic expansion chuck SK 50-32-91 DIN 69871 AD/B in wooden box

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Delivery:

With wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

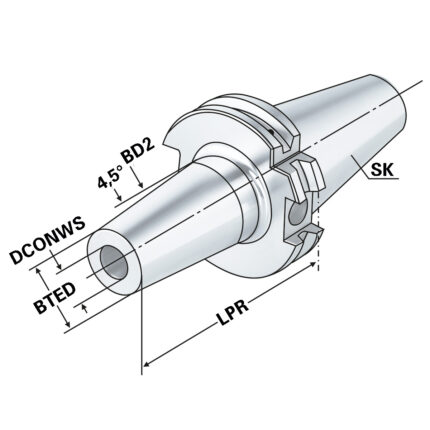

Shrink chuck 4,5° SK 40 – 16 – 120

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance8

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Vierkant-Mehrfach-Aufnahme – form D2 overhead 40 – 25 – 72

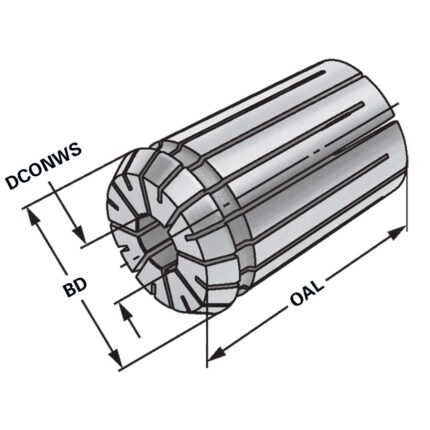

OZ-Collet OZ32 | 467E | < 15µm | O 19 - 18,5

KPS-Collet chuck SK 40 – 4/16 – 160 | KPS 16

Application:

For mounting straight-shank tools in collets. To use for high speed cutting and high precision milling.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

End mill holder Weldon PSK 63 – 40 – 100

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

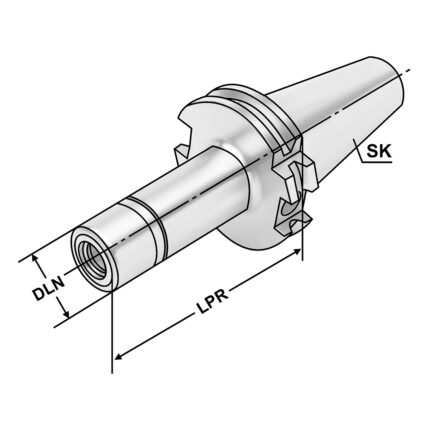

Morse taper adaptor SK 50 – 3 – 65

Application:

For clamping tools with Morse taper shank and thread according to DIN 228-1 form A.

Delivery:

With built-in tightening bolt

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

HSS-E spiral flute taps M3 3,5×2,7 P=0,5

Application:

1. Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

2. Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

3. Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel