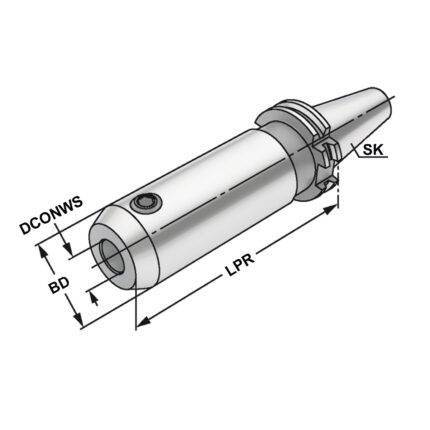

End mill holder Weldon SK 50 – 18 – 100

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Milling arbors for screw-in cutters SK 40 – M16 – 69 – LB50

Application:

For mounting screw-in cutters with thread.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

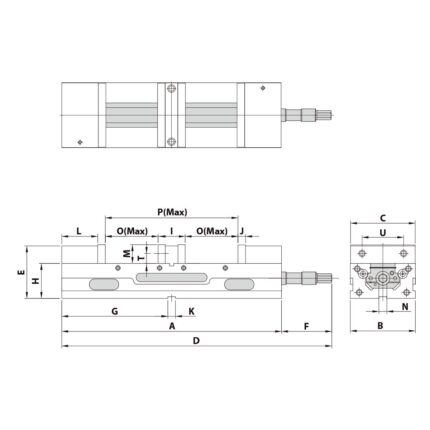

Twin vice TLD-60G/HV mechanical

Construction:

- Double-clamping via two mobile and one fixed jaw.

- Clamping positions: horizontal, and vertical

- The steel body is hardened and grinded all-round

- Integrated pull-down mechanism

- Repeating accuracy 0,01 mm

- Clamping accuracy at the centre 0,01 mm

- Bed height H: 0,01 mm

Delivery:

- Instructions for use

- Wrench

- 4 pcs. vice clamps

- 4 pcs. T-nuts 18 mm

- Test certificate

Angular milling cutter 90° 160mm – 40mm without coolantAPKT 1604 / APHX 1604

HSS-E spiral flute taps M22 18×14 P=2,5

Application:

1. Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

2. Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

3. Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

Hydraulic expansion chuck HSK 63 – 20 – 150

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth

l2 = max. length adjustment range

Delivery:

Without wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined