PART OF CATALOG

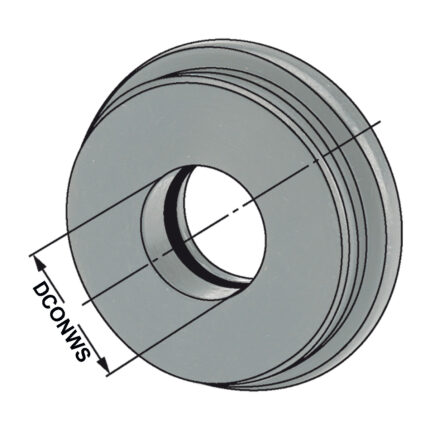

Sealing disc | ER 40 DCONWS = 2,5

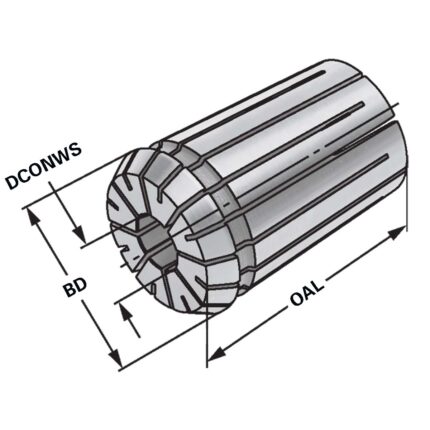

OZ-Collet OZ16 | 415E | < 15µm | O 2 - 1,5

Clamping sleeves for taps with quick change DCONMS=20 | 8 x 6,2

OZ-Precision collet OZ25 | 462EP | < 5µm | O 25 - 24,5

ER-Gewindebohrer-Spannzange IK ER40 | 472GA | < 15µm | 14 x 11

Shrink chuck 4,5° with cooling channels SK 40 – 08 – 80

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

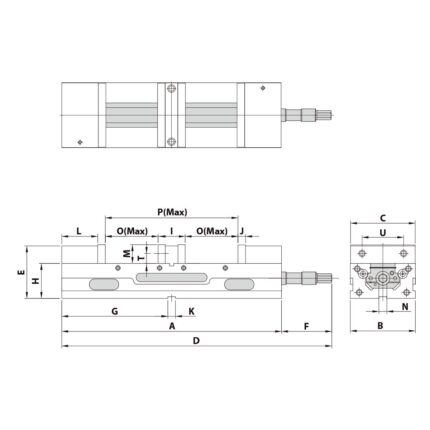

Twin vice TLD-60G/HV mechanical

Construction:

- Double-clamping via two mobile and one fixed jaw.

- Clamping positions: horizontal, and vertical

- The steel body is hardened and grinded all-round

- Integrated pull-down mechanism

- Repeating accuracy 0,01 mm

- Clamping accuracy at the centre 0,01 mm

- Bed height H: 0,01 mm

Delivery:

- Instructions for use

- Wrench

- 4 pcs. vice clamps

- 4 pcs. T-nuts 18 mm

- Test certificate

FREE CONSULTATION