HSSE twist drill 135° 3,9 mm DIN 338 | TIN coating

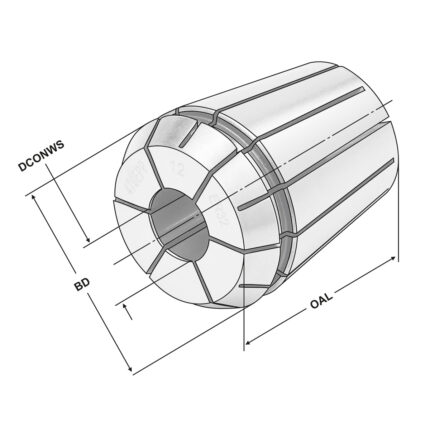

ER-Precision collet ER32 | 470EPP | < 3 µm | O 11,5

Application:

For mounting straight-shank tools in collet chucks ISO 15488 (ex. DIN 6499).

Version:

System concentricity and repetition accuracy 3 µm (3?D, maximum = 50 mm), in conjunction with KEMMLER Precision collet chuck ER".

Suitable for:

KEMMLER Precision collet chuck ER or standard collet chuck Spannfutter ISO 15488 (ex. DIN 6499).

Note:

The collet clamping O range is always up to 0.5 mm less than nominal.

ER-Gewindebohrer-Spannzange IK ER40 | 472GA | < 15µm | 9 x 7

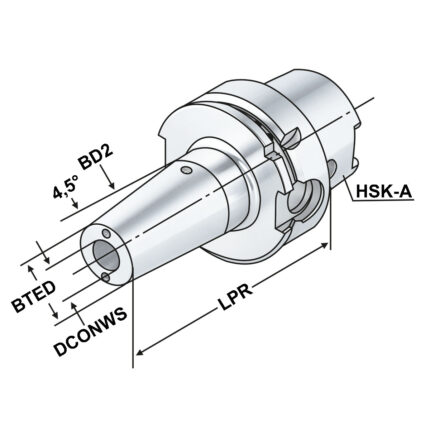

Shrink chuck 4,5° with cooling channels HSK 63 – 06 – 80

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

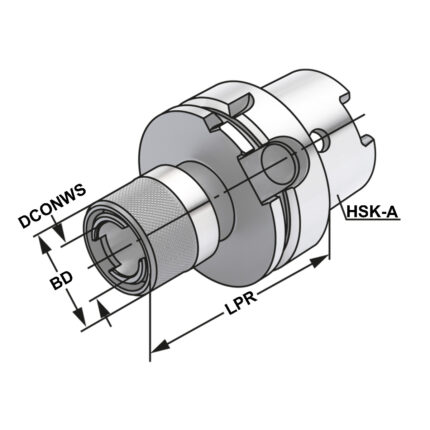

Quick change tapping chuck HSK 100 – M14-M36 – Gr.3

Application:

For the chucking of quick change adaptors for taps.

Note:

For machining centres with synchronous spindle.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

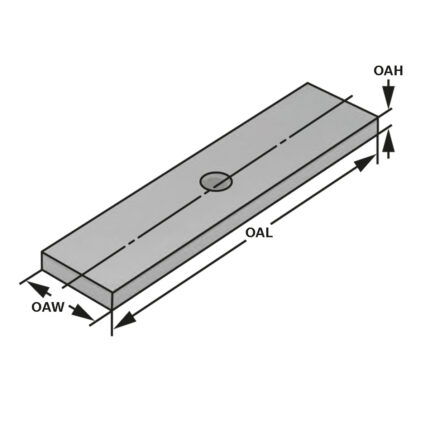

Coolant tube HSK 100

Application:

For the coolant supply through the centre of HSK toolholders.

Note:

Axial sealed with two O-rings. After mounting, the coolant tube can be moved only to a minimum degree according to DIN (±1°).

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Vernier height gauge | analogue | 0 – 300 mm 1/128″ | reading 0,05mm

Construction:

- Graduation: 0.05mm / 1/128"

- The fine-adjustment allows the slider to be precisely positioned

- Matt chrome finish

- Stainless steel design

- The base is designed with a thermal heat isolation hand grip

Delivery:

- Carbide tipped scriber with clamp

- Warranty card

- Instruction manual

- Calibration certificate