Thermal Printheads

Thermal printheads are devices used to print using thermally sensitive materials (i.e. thermal paper, thermal transfer ribbon) by energizing resistors mounted on a substrate to generate joule heat.

Thermal paper, which is low-cost, easy to handle, and virtually maintenance-free, is used in wide variety of applications, including fax machines, printers, and ticketing equipment.

What’s more, improved characteristics such as recording quality and speed have expanded the application range.

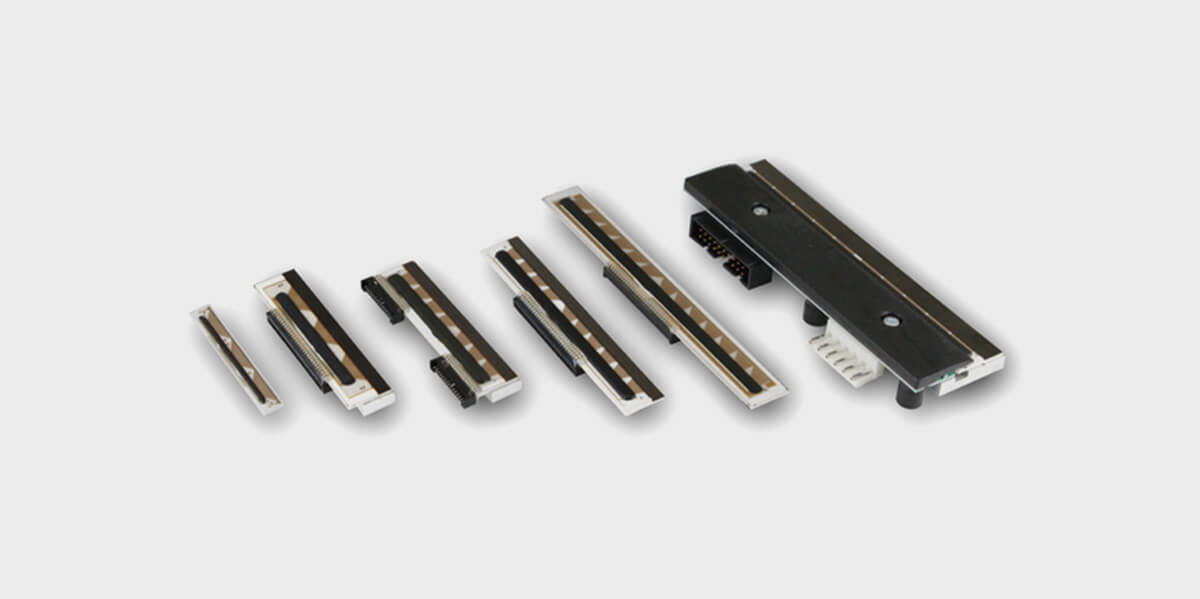

Thermal printheads are roughly classified into thick-film and thin-film types based on the manufacturing method, materials, and structure.

ROHM offers both types, along with hybrid products that combine thick- and thin-film elements in original configurations.

[Thermal Printhead Manufacturing Method Comparison]

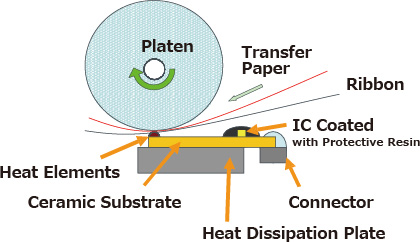

Thermal Transfer Method

A method in which a wax or resin-based ink tape (ribbon) is melted (glued) onto a material such as paper using heat.

[Thermal Printhead Manufacturing Method Comparison]

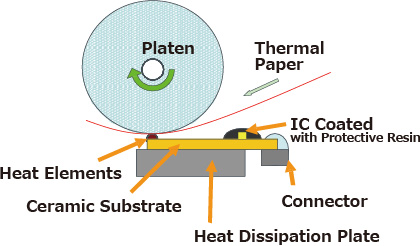

Thermal Method

A method of printing achieved by contacting heat elements with thermal paper (special heat-sensitive paper). Frequently used for receipt printers.