ZZC-CT tooling

Product Innovations 3/20

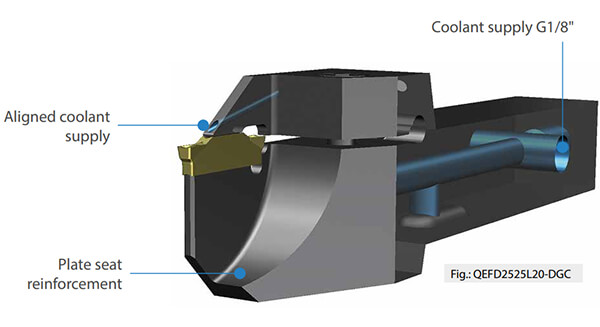

Precision monoblock holder

With internal cooling

With internal cooling

SC Grooving system (for sliding head lathe machines)

Shank sizes ranging from 10×10 to 20×20 mm

Grooving widths from 2.0 to 3.0 mm

DG(S)C Grooving system (for greater depths)

Shank sizes ranging from 16×16 to 25×25 mm

Grooving widths from 2.0 to 6.0 mm

YOUR BENEFITS

Product Innovations 9/20

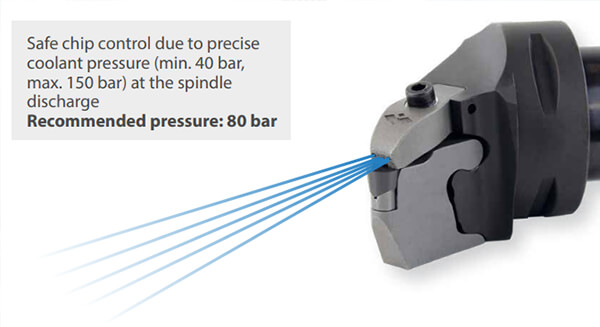

- 100% chip control during machining of long chipping workpiece materials

- Economic design of the tool system with an interchangeable cassette, to minimize tool damage in case of crash

- Cassette available in alternative materials where needed

- The interlocking between cassette and base holder guarantees maximum rigidity and security

- The clamping system additionally reduces vibrations

- Holders are available with any relevant machine tool interface

Primary workpiece materials

Main industry segments and components

Large diameter bearing industry