Labelling and marking: cleaning before labelling and marking on metals and plastics.

Historic & art restoration: cleaning the fine layers of dust, grease ect. off paintings & artwork.

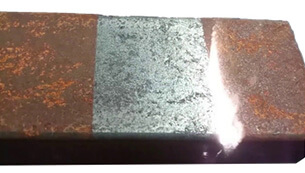

Rust removal: removing rust from old steel parts or concrete.

Paint cleaning: the removal of paint from a surface.

Mold cleaning: the cleaning of molds after use, such as baking plates, tire molds, etc.

Railway tracks: removing dirt, grime, wet leaves, etc. for smooth operations.

Preparation treatment: removal of lubricants, contaminants, grease, oils, etc. for surface preparation.

Tool cleaning: you can clean tools with fiber laser easily.

Stone restoration: the cleaning of buildings, ornaments and sculptures that are made of stone.